HISTORY: One Reputation, Real Values

Since 1908, Komar Brands has led in apparel design, sourcing, and manufacturing. Since launching Komar Distribution Services in 1998, the company has excelled in B2B, Ecommerce fulfillment, and value–added services for over 100 brands and 500 retailers in 50 categories, committed to exceptional service and supply chain mastery

CULTURE

Komar Distribution Services prides itself on a culture of integrity, respect, and professionalism, encapsulated in our ‘One Reputation Real Values’ philosophy. ‘Execute and Good Things Will Happen’ is more than a slogan—it’s the heartbeat of our proactive work environment. We believe in the power of dedication and data in fostering excellence, with a focus on continual improvement, learning, and mastery in our tasks.

TEAM

Dedicated and proficient team of 250 members

Remarkable 5+ year average tenure

90% equipped with cross-training for enhanced resilience

Culture fostering internal career growth

SERVICE LEVEL EXCELLENCE

99.95% Operational Fill Rate

99.95% Inventory Accuracy

99.93% Operational Chargeback Compliance

99.93% Operational On Time Shipping

CAPABILITIES

Robotic Pick and Pack

Cross Dock Carton in/Carton Out

E-Commerce

Transload

Drayage

Domestic Transportation

Added Value Services and Kitting

Small Parcel Carrier Management including Rate Shop

Proprietary Production Planning and Balanced Workload Technology for improved compliance and customer satisfaction

PRODUCTION

Daily Receiving – 60 Containers

Daily Cases 80,000 – Labeled, Staged, Routed and Shipped

Daily Ecommerce 65,000 packages

Reserve Storage 120,000 Pallets

Multi-Shift for SLA excellence

ROBOTIC ECOMMERCE AND PICK/PACK PRCOCESSING

HIGH-SPEED FULFILLMENT:

Boosts efficiency, reduces order processing time.

Peak capacity 60,000 units daily.

FASTER LEAD TIMES:

Automation reduces order processing time.

SCALEABLE:

Adaptable to changing demands.

PRECISION:

Minimizes errors, improves order accuracy.

KPIs

Accuracy: 99.95

On Time SLA 99.92

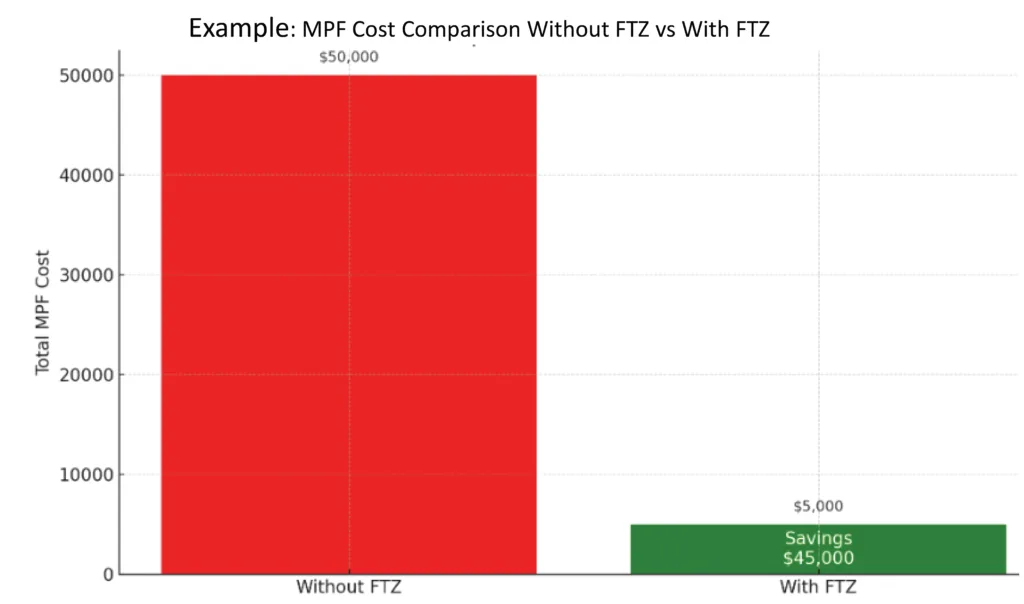

FOREIGN TRADE ZONE MANAGEMENT

Since 2016 Komar Distribution has saved millions of dollars in interest and processing fees.

DUTY DEFERRAL

Duty deferral in a Foreign-Trade Zone improves businesses’ cash flow by postponing tax payments until goods leave the zone, which saves on interest costs and frees up capital for other uses. Unlike a bonded warehouse there is no limit on the length of time that merchandise may remain within the Zone.

MERCHANDISE PROCESSING FEE (MPF) REDUCTION

By allowing FTZ users to consolidate shipments into a single entry for a week’s worth of goods, rather than filing for each shipment, significant savings are realized.

STREAMLINED LOGISTICS

Upon approval from Customs, users can take advantage of direct delivery to the FTZ.

OTHER BENEFITS

Improved inventory management and security can enhance adherence to Customs and Border Protection (CBP) regulations, potentially reducing security and insurance costs. FTZ merchandise is exempt from insurable value calculations, which can further decrease insurance expenses.

KOMAR DRAYAGE BENEFITS

Since 2016 Komar Distribution has saved millions of dollars in interest and processing fees.

EFFICIENT TURN TIMES

Minimize waiting times and rollovers with 24/7 off-peak service.

OWNED CHASSIS POOL

Reduce potential delays and shortages for predictable deliveries.

ADVANCED TECHNOLOGY INTEGRATION

Real-time tracking and automation for better visibility and operations.

STRONG NETWORK AND PARTNERSHIPS

Solid terminal relationships for seamless operations.

CLEAR COMMUNICATION

Timely updates for informed customers.

EXPERIENCED STAFF

Skilled team for smooth operations.

CUSTOM SOLUTIONS

Tailored answers for unique logistical needs.

KPIs

Rollover of Scheduled Loads 2%

On Time Pickups 98%

Average Container Yard Dwell 3.4 days

Detention and Demurrage 0.03%

KOMAR TRANSLOADING

Process optimization with advanced technology.

TECHNOLOGY INTEGRATION

Scheduling, tracking and execution through real-time dashboards and stakeholder integration.

OWNED CHASSIS POOL AND EQUIPMENT

Mitigate potential delays and shortages. Achieve predictable Deliveries

FLEXIBILITY AND SCALABILITY

Multi-shift to accommodate for volume fluctuations, cargo types and urgent turns.

STRONG NETWORK AND PARTNERSHIPS

Solid terminal relationships for seamless operations and minimized expenses.

CLEAR COMMUNICATION

Timely updates for informed customers.

EXPERIENCED STAFF

Skilled team with integrated technology for smooth operations.

TRANSLOADING KPIs

SLA Achievement 99.96%

Average Container Yard Dwell 3.4 days

Detention and Demurrage 0.03%

SUPPLY CHAIN MANAGEMENT

Komar Logistic Services collaborates with ACS and Infor Nexus TMS to forge an integrated supply chain management ecosystem

VISIBILITY ACROSS THE SUPPLY CHAIN

Monitor shipments in real-time and identify potential disruptions before they become major issues.

COLLABORATION

Bring stakeholders onto a single platform. Shippers, carriers, suppliers, and other partners collaborate in real-time, enhancing communication and decisions.

COST CONTROL

Optimize transportation expense, routes and modes with advantageous KDS rates, achieve significant cost savings including auditing, settlement and error detection in billing.

FLEXIBILITY

Adapts to industry needs and responds to changes in business operations or market shifts.

ANALYTICS AND REPORTING

Advanced analytics help businesses identify trends, understand performance metrics and make informed decisions.

CUSTOM SOLUTIONS

Tailored answers for unique logistical needs including ERP and WMS integration

KPIs

On Time Inventory to Sales Order Ship Date Compliance 99.94%

Ocean Container Utilization 99.3%

KOMAR MANAGED SUPPLIER REPLENISHMENT INVENTORY

Enhancing sales and cutting surplus with a managed approach to streamline collaboration and supply chain efficiency between a supplier’s owned inventory and retailers.

Sophisticated Inventory Management

Komar Support Services employs an advanced inventory management technique by calculating the supply duration for each product. This strategy ensures stock levels are adjusted based on historical sales and future forecasts, aiding in inventory balance, minimizing surplus, and preventing shortages.

Detailed Sales Tracking

The system provides in-depth sales tracking at the store level, offering insights into performance across various locations. This tailored approach helps in making precise inventory decisions for each store, enhancing sales potential and ensuring customer satisfaction through optimal stock levels.

Proactive Replenishment Planning

By utilizing advanced analytics, Komar predicts when products are likely to run out and identifies restocking triggers. This proactive planning maintains product availability and avoids excessive inventory storage.

Expert Inventory Optimization

An inventory specialist at Komar guides suppliers and retailers in aligning their stock levels with both forecasted and actual sales. This process includes spotting discrepancies, recommending corrective measures to achieve sales targets, and fine-tuning inventory to prevent overstocking or understocking, ensuring the business adapts to market trends and remains competitive.

KOMAR BACK OFFICE MANAGEMENT

For businesses focusing on design, sales, and manufacturing, Komar Support Services manages all back office functions to boost growth and profitability.

Financial Management: Precision in Financial Operations

Style and Sales Order Management: Enhancing Product Catalog and Order Processing Efficiency

Sales Order Allocation: Strategic Inventory Allocation for Timely Fulfillment

Production Order Management: Integrated Production Planning for Demand Fulfillment

Supply Chain Management: Collaborative and Real-Time Supply Chain Optimization

Inventory Management: Precision in Inventory Control and Optimization

Analytics and Reporting: Data-Driven Insights for Strategic Decision-Making

Project Management: Comprehensive Management of Business Process Lifecycles

KOMAR OFFSHORE BUSINESS SUPPORT SERVICES

A comprehensive suite of support functions tailored for companies seeking to offshore these operations

Leverage Sri Lanka’s advantageous strategic location and time zone for uninterrupted 24/7 operations.Optimize operational costs through access to a highly skilled workforce, advanced infrastructure and operational excellence.

Retouching: Visual Content Enhancement

2D and 3D Pattern Making

Sample Making: Prototype Development Services

Production Management: Efficient Production Management Support

Customer Service: Responsive Support Solutions

Design Development: Creative Product Innovation and Support

Transportation Management: Logistic Efficiency Optimization

Routing: Shipment Support

Other Backoffice Functions: Comprehensive Support Solutions

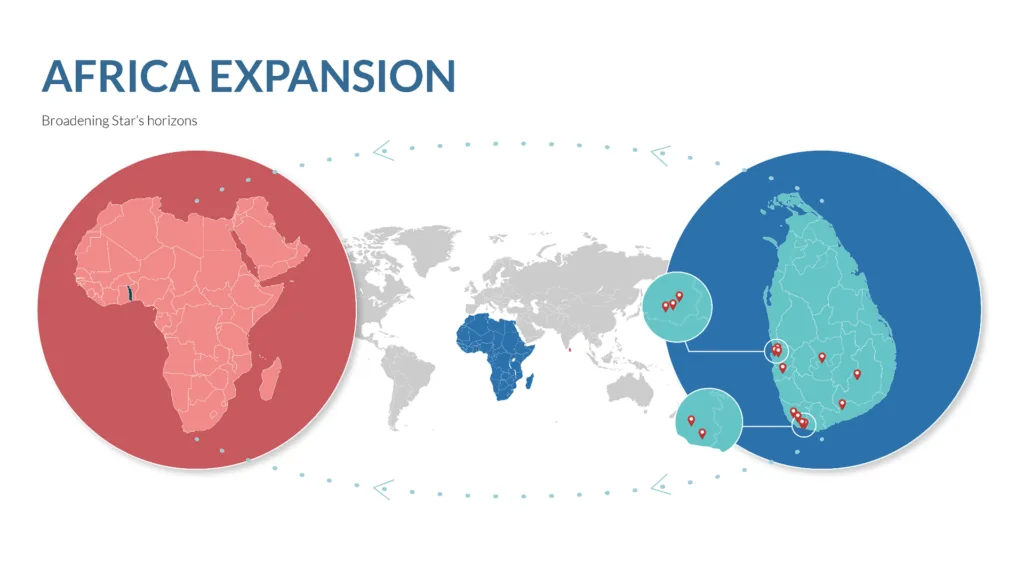

STAR GARMENTS GROUP:

Sourcing and manufacturing at its best

Decades of Experience and Technical Expertise

Rooted in Sri Lanka, Star leverages extensive expertise to manufacture over 40 product categories for prestigious fashion brands in the US, UK, and Europe, utilizing deep technical knowledge.

Investment in Virtual 3D Product Development

Positioned as Sri Lanka’s leading digital studio, producing 600 high-quality digital renderings monthly with platforms like Clo and Browzwear, pioneering industry standards.

Commitment to Responsible Manufacturing

Sustainability leader with eight LEED-certified facilities in Sri Lanka, the world’s first certified carbon-neutral apparel manufacturing conglomerate, including South Asia’s first certified ‘Passive House’ sustainable headquarters.

Expanding Horizons: Strategic Global Growth

Building on its Sri Lankan base, the recent strategic expansion into Togo enhances Star’s global manufacturing capacity, leveraging the strategic location near the Port of Lomé for efficient global distribution.

Impact of Apparel Import Duty Exemption in Togo

The removal of apparel import duties for exports from Togo to major markets such as the US, Canada, EU, UK, and Australia makes Togo manufacturing financially attractive, significantly lowering the landed cost of goods and fostering growth.

DISTRIBUTION & SUPPLY CHAIN TECHNOLOGY

BEST IN CLASS OPERATING SYSTEMS

Manhattan, Infor Nexus, All Port Cargo Services, Tompkins Robotics, EasyMetrics, OptiSlot DC, PortPro, TradeLink, Integration Point, and CGS/Blue Cherry.

TECHNOLOGY AND INNOVATION

Integrates systems and data with business operations.

KDS IT INFRASTRUCTURE

Defense In Depth Data Protection

3X Data Redundancy and Connectivity

Reliable and Optimized Next Generation Wireless Infrastructure

IT Service Availability 99.99%

ISO 27001 Security Practices

ISO 27031 Disaster Recovery and Business Continuity

Multi Certified IT Specialists

FURTHER INFORMATION

- Komar Distribution Spring 2024 Newsletter

- Komar Distribution T Sort Tour

- Newsletter Signup and Share

- Information Request: hansani.bandara@komardistribution.com

Warmly,

The Komar Distribution Services Team